ROBOTIS Dynamixel MX-64AR

4 Pin RS-485 Servo Robot Actuator with Aluminum Front Plate

ROBOTIS Dynamixel MX-64AR 4 Pin RS-485 Servo Robot Actuator with Aluminum Front Plate

#902-0097-000

Get a Quote!

Package Components

- MX-64AR

- HN05-N102

- Thrust Washer (for horn)

- 4P Cable 200mm

- 16 x Wrench Bolt WB M2.5x4

- 1 x Wrench Bolt WB M3x8

- 18 x Nut M2.5

Click here to jump to more pricing!

Overview:

The MX-64AR Dynamixel Robot Servo Actuator with Aluminum Front Plate is the newest generation of Robotis Dynamixel actuator; equipped with an onboard 32bit 72mhz Cortex M3, a contact-less magnetic encoder with 4x the resolution over the AX/RX series, and up to 3mpbs using the new RS-485 2.0 bus. Each servo has the ability to track its speed, temperature, shaft position, voltage, and load. As if this weren't enough, the newly implemented PID control algorithm used to maintain shaft position can be adjusted individually for each servo, allowing you to control the speed and strength of the motor's response. All MX Series servos use 12v nominal voltage, so other MX-R series Dynamixels can be mixed without having to worry about separate power supplies. All of the sensor management and position control is handled by the servo's built-in microcontroller. This distributed approach leaves your main controller free to perform other functions.

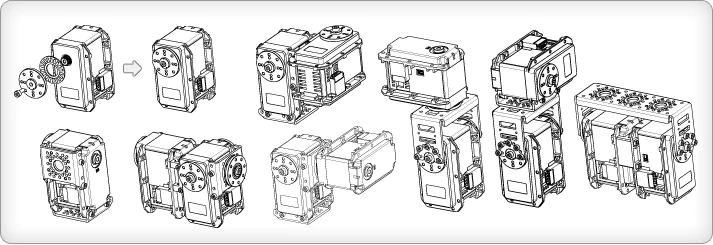

Dynamixel is a robot exclusive smart actuator with fully integrated DC Motor + Reduction Gearhead + Controller + Driver + Network in one DC servo module.

- Advanced durability, degree of precision, and wider control zone were achieved thanks to the newly applied contactless absolute encoder

- 360 degrees position control without dead zone

- 4,096 precise resolution by 0.088 degrees

- Speed control at endless turn mode

- Reliability and accuracy were advanced in the position control through PID control

- High baud rate up to 4.5Mbps

Shape of the AX-series + durability of the MX-series

The MX-series is a new type of DYNAMIXEL with numerous advanced functions, such as precise speed control, 360 degrees of accurate positioning, PID control, and high speed communication.

![]()

The MX actuator contains a new contactless magnetic rotary encoder for accurate angular movement over a full 360 degrees.

![]()

The absolute angle measurements provide instant and reliable information of the angular position with a resolution of 12 bits = 4096 positions within 360 degrees. This delivers fine angle movements accurate to 0.088 degrees.

![]()

The MX-series also integrates a new PID Control, which automatically and accurately corrects for naturally occurring errors such as backlash (caused by small gaps in the gears). Thus, positioning is more reliable and in compliance to specifications.

Precise speed is controlled through serial data and has a resolution of 10 bits to accurately adjust the high speed movements into 1023 increments of speed control.

Actuator status, commands, and sensor information are easily provided through readable memory and made available as a serial bit stream through TTL communication with a baud rate of up to 4.5 Mbps (4,500,000 bits per second).

Flexible Construction And Modular Structures

Package Components

- MX-64AR

- HN05-N102

- Thrust Washer (for horn)

- 4P Cable 200mm

- 16 x Wrench Bolt WB M2.5x4

- 1 x Wrench Bolt WB M3x8

- 18 x Nut M2.5

Compatible Products

- Controller: CM-2+, CM-700, OpenCM9.04(+ OpenCM485 Expansion Board), OpenCR

- Interface: USB2Dynamixel, U2D2

Factory Default Settings

- ID: 1

- Baud Rate: 57600bps

(User can change various settings including ID and baud rate according to environment)

Features and Benefits:

Key Features:

- Contactless motion and position sensing

- High resolution for precise movements

- Standard TTL communication interface

- High speed communication up to 4.5 Mbps

- PID Control for auto-correction in positioning

Key Benefits:

- High reliability and durability

- Control of high precision movements

- Control of high speed movements

- Easy to use

Aluminum Front Plate:

Specifications:

| Specifications | |

|---|---|

| MCU | Cortex-M3 (72 Mhz, 32 bit) |

| Input Voltage | Min: 10.0V Recommended: 12.0V Max: 14.8V |

| Performance Characteristics | Voltage: 12.0V Stall Torque: 6.00N·m Stall Current: 4.1A No Load Speed: 63.0rpm No Load Current: 0.15A |

| Continuous Operation | Voltage [V]: -

Torque [N·m]: - Speed [rpm]: - Current [A]: - |

| Resolution | Resolution [deg/pulse]: 0.0879

Step [pulse]: 4,096 Angle [degree]: 360 |

| Position Sensor | Contactless Absolute Encoder (12 [bit], 360 [deg]) Maker: ams(www.ams.com), Part No: AS5045 |

| Operating Temperature | Min: -5 °C Max: 80 °C |

| Motor | Coreless (Maxon) |

| Baud Rate | Min: 8,000 bps Max: 4,500,000 bps |

| Control Algorithm | PID |

| Gear Type | Spur |

| Gear Material | Metal |

| Case Material | Metal(Front) Engineering Plastic(Middle, Back) |

| Dimensions (WxHxD) | 1.58 X 2.41 X 1.61 inch (40.2 X 61.1 X 41 mm) |

| Weight | 4.76oz (135.00g) |

| Gear Ratio | 200 : 1 |

| Command Signal | Digital Packet |

| Protocol Type | Half duplex Asynchronous Serial Communication (8bit, 1stop, No Parity) |

| Link (Physical) | RS485 Multi Drop Bus |

| ID | 0 ~ 253 |

| Feedback | Position, Temperature, Load, Input Voltage, etc |

| Protocol version | 1.0(Default) 2.0 |

| Operating Mode / Angle | Wheel Mode:Endless turn Joint Mode:360 [deg] Multi-turn Mode:±28 [rev] |

| Output | - |

| Standby Current | 100 mA |

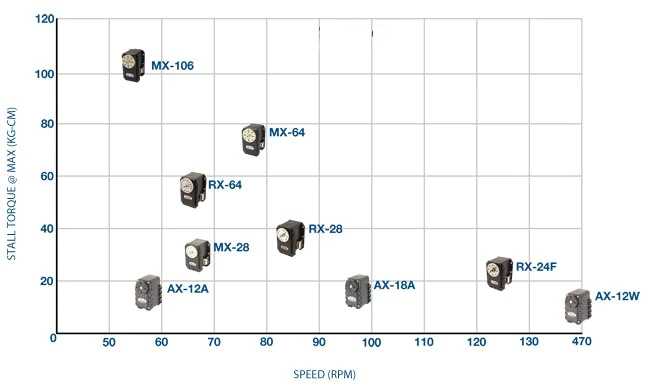

Performance Comparison:

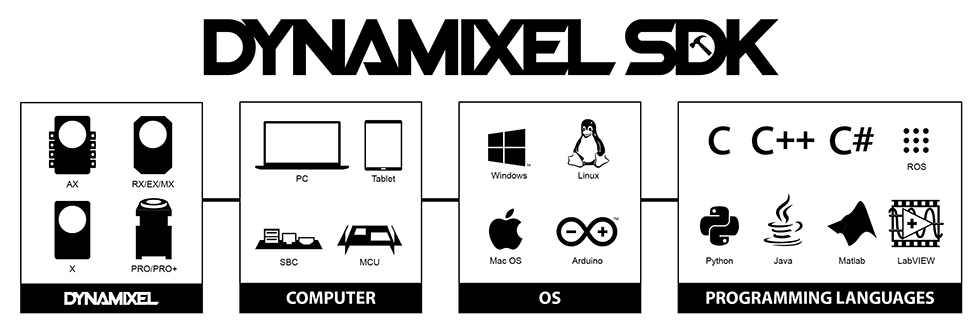

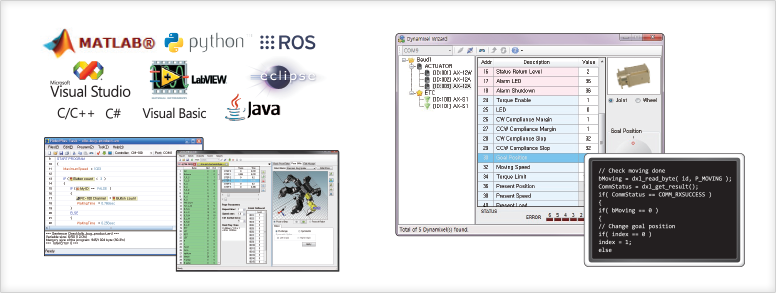

Dynamixel SDK:

Provides various control environment just like Dynamixel

Dynamixel SDK is a software development kit that provides Dynamixel control functions using packet communication. The API of Dynamixel SDK is designed for Dynamixel actuators and Dynamixel-based platforms. You need to be familiar with C/C++ programming language for right use of the software. This e-Manual provides comprehensive information on ROBOTIS products and applications.

Supported Protocols

To control Dynamixel, communication should be established according to the protocol of Dynamixel. There are versions 1.0 and 2.0 of the Dynamixel protocol. The Dynamixel SDK supports both, and the user can use both protocols simultaneously using the Dynamixel SDK. Refer to the following manuals for details on the protocols.

- Dynamixel Protocol 1.0

- Dynamixel Protocol 2.0 (Recommended protocoltype)

Supported Devices

The Dynamixel SDK can be used on PCs such as desktops or laptops, as well as on tablets, and also on SBCs like Raspberry Pi and UpBoards. In addition, it can be used with embedded boards that support the Arduino IDE. Dynamixel uses TTL and RS485 communication. In order to use computer and Dynamixel, we recommend USB2Dynamixel or U2D2 as interface device.

Supported Operating Systems

The Dynamixel SDK supports all three operating systems: Windows, Linux, and MacOS.

Supported Languages

The Dynamixel SDK supports various programming languages: C, C++, C#, Python, Java, MATLAB and LabVIEW.

In addition, Dynamixel SDK supports ROS, so it can be used as ROS library using C++ or Python modules.

- C: *Dynamic library and source code of this library and examples

- C#, Java, MATLAB, LabVIEW: Support based on dynamic library using C language

- C++: *Dynamic library and source code of this library and examples

- Python: Python module and examples

- ROS: ROS library using C++ and Python modules

(* Dynamic library (*.dll, *.so, and *.dylib files) / .dll: dynamic-link library on Windows / .so: shared object on Linux / .dylib: dynamic library on macOS)

Video:

Pricing Notes:

- Pricing and product availability subject to change without notice.

Get a Quote!

Get a Quote!