ROBOTIS Dynamixel PH42-020-S300-R

Dynamixel Pro Servo Robot Actuator

Package Components

- PH42-020-S300-R

- Robot Cable-X4P 300mm (Convertible

- Robot Cable-X4P 300mm

- 20 x Wrench Bolt WB M3x8

Overview:

All Dynamixel Pro servo are rated at 24 V, use the RS-485 communication protocol, and are designed for an operating temperature from 5-55 C (41-131 F). Additional model specifications, dimensional drawings, 3D models, software downloads, and documentation can be found on the individual product pages.

Dynamixel is a robot exclusive smart actuator with fully integrated DC Motor + Reduction Gearhead + Controller + Driver + Network in one DC servo module.

Dynamixel-P Series implements removable reduction cycloid gears, resulting in high precision and impact resistance.

- Torque control based on current sensing

- Position, Torque and Speed-based command

- High resolution with combination of Incremental Encoder and Contactless Absolute Encoder

- Full metal housing for high durability

- Can be used to make a full-size manipulator, pan tilt, humanoid, etc.

Dynamixel Pro -> P Upgrade Details

- Improved design and JST connectors applied

- Improved dirt inflow and leakage

- Improved control table (Supports X Series functions)

- Enhanced control performance such as responsiveness and resolution

- Enhanced communication responsiveness

- Improved heat, noise, and durability

Package Components

- PH42-020-S300-R

- Robot Cable-X4P 300mm (Convertible

- Robot Cable-X4P 300mm

- 20 x Wrench Bolt WB M3x8

Compatible Products

- Controller: OpenCM 485 Expansion Board, OpenCR1.0

- Interface: USB2Dynamixel, U2D2

Factory Default Settings

- ID: 1

- Baud Rate: 57600bps

(User can change various settings including ID and baud rate according to environment)

Caution

The operational voltage is different from other DYNAMIXEL series (Operational voltage: 24V).

Depending on the number of units used, it is recommended to use a separate power supply.

JST 4Pin connector is applied for communication.

The 42 series uses the same hinge frames.(FRP42-H110/120)

Features:

Features:

- 1,000 pulse incremental encoder before gear reduction

- 4,096 step absolute encoder after gear reduction

- Electrical current sensing based control

- Internal temperature sensing

- Position-based command

- Torque-based command

- Speed-based command

- Cycloid type detachable reduction gear (Straight, Right Angle, Belt)

- Various communication physical layer

* Supports RS-485

* CAN, TTL, EtherCAT [Coming Soon] - Various optional frame

Specifications:

| Specifications | |

|---|---|

| MCU | Cortex-M4 (168 Mhz, 32 bit) |

| Input Voltage | Min: - Recommended: 24.0V Max: - |

| Performance Characteristics | Voltage: 24.0V Stall Torque: - Stall Current: - No Load Speed: 32.7rpm No Load Current: 0.57A |

| Continuous Operation | Voltage: 24.0V Torque: 5.1N.m Speed: 29.2rpm Current: 1.5A |

| Resolution | Resolution [deg/pulse]: 0.0006

Step [pulse]: 607,500 Angle [degree]: 360 |

| Position Sensor | Contactless Absolute Encoder Incremental encoder |

| Operating Temperature | Min: -5 °C Max: 55 °C |

| Motor | Coreless (Maxon) |

| Baud Rate | Min: 9,600 bps Max: 10,500,000 bps |

| Control Algorithm | PID |

| Gear Type | Cycloid |

| Gear Material | Metal |

| Case Material | Metal |

| Dimensions (WxHxD) | 1.65 x 3.31 x 1.65 inch (42.0 x 84.0 x 42.0 mm) |

| Weight | 11.99oz (340.00g) |

| Gear Ratio | 303.8 : 1 |

| Command Signal | Digital Packet |

| Protocol Type | Half duplex Asynchronous Serial Communication (8bit, 1stop, No Parity) |

| Link (Physical) | RS485 Multi Drop Bus |

| ID | 0 ~ 252 |

| Feedback | Position, Velocity, Current, Temperature, Voltage, External Port, etc |

| Protocol version | Protocol 2.0 |

| Operating Mode / Angle | Torque Control Mode Velocity Control Mode Position Control Mode Extended Position Control Mode PWM Control Mode |

| Output | 20W |

| Standby Current | 30 mA |

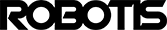

Performance Comparison:

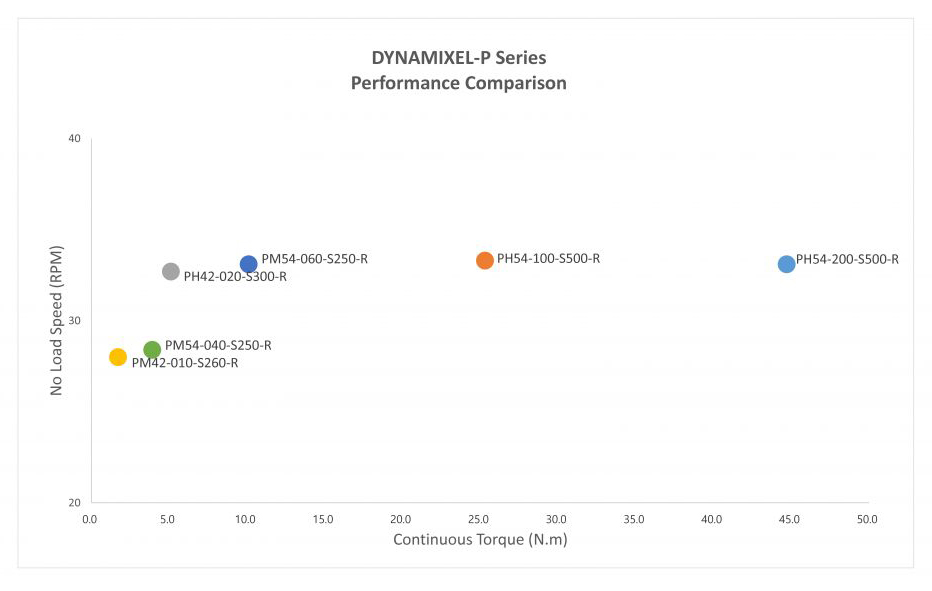

Dynamixel SDK:

Provides various control environment just like Dynamixel

Dynamixel SDK is a software development kit that provides Dynamixel control functions using packet communication. The API of Dynamixel SDK is designed for Dynamixel actuators and Dynamixel-based platforms. You need to be familiar with C/C++ programming language for right use of the software. This e-Manual provides comprehensive information on ROBOTIS products and applications.

Supported Protocols

To control Dynamixel, communication should be established according to the protocol of Dynamixel. There are versions 1.0 and 2.0 of the Dynamixel protocol. The Dynamixel SDK supports both, and the user can use both protocols simultaneously using the Dynamixel SDK. Refer to the following manuals for details on the protocols.

- Dynamixel Protocol 1.0

- Dynamixel Protocol 2.0 (Recommended protocoltype)

Supported Devices

The Dynamixel SDK can be used on PCs such as desktops or laptops, as well as on tablets, and also on SBCs like Raspberry Pi and UpBoards. In addition, it can be used with embedded boards that support the Arduino IDE. Dynamixel uses TTL and RS485 communication. In order to use computer and Dynamixel, we recommend USB2Dynamixel or U2D2 as interface device.

Supported Operating Systems

The Dynamixel SDK supports all three operating systems: Windows, Linux, and MacOS.

Supported Languages

The Dynamixel SDK supports various programming languages: C, C++, C#, Python, Java, MATLAB and LabVIEW.

In addition, Dynamixel SDK supports ROS, so it can be used as ROS library using C++ or Python modules.

- C: *Dynamic library and source code of this library and examples

- C#, Java, MATLAB, LabVIEW: Support based on dynamic library using C language

- C++: *Dynamic library and source code of this library and examples

- Python: Python module and examples

- ROS: ROS library using C++ and Python modules

(* Dynamic library (*.dll, *.so, and *.dylib files) / .dll: dynamic-link library on Windows / .so: shared object on Linux / .dylib: dynamic library on macOS)

Video:

Pricing Notes:

- Pricing and product availability subject to change without notice.